Colour masterbatches

Description

Masterbatches for polymers mass colouring are concentrates that transform thermoplastic and thermoset polymers from colourless and opaque materials to brilliant and coloured. The craft of polymer colouring is not only a matter of knowing the basics of the colours perception optical phenomena, but also understanding the reactions that pigments and dyes can have with base resin, mineral fillers and additives as well as the material final application and the processes undertaken. There are soluble colorant substances (dyes) and insoluble substances (pigments) that can be organic or inorganic, natural or synthetic. Combinations of these types of ingredients are contained in the modern masterbatches along with other non-colouring additives. It is through this complexity that it is possible to develop strength, depth and resistance to colours.

Some of the masterbatch must-have characteristics required by the market are:

- High concentration for a high coverage capacity with low impact on the polymer’s properties

- Uniform distribution for high-throughput processes

- Easy dosing for process automation

- Stability at process conditions

- Stability at employment conditions

- Transparency or opacity based on request

- Possibility to create special effects such as fluorescence, opalescence, glittering etc.

- Absence of heavy metals or harmful ingredients for the manufacturing of articles in contact with food, potable water or medical devices, etc.

Processing

Among the different colouring technologies available to process polymers, MESGO Iride Colors can supply masterbatches in granules pastes, liquid and predispersed powders. In all these four cases, the dispersion of different components is obtained at high shear by using available technologies to process the polymers. Another important aspect is the colour matching, mainly obtained by preparing a countertype on customer’s request and by imitating from the reference colour table (RAL or Pantone) or transferring one colour from one material to another.

Processing

Among the different colouring technologies available to process polymers, MESGO Iride Colors can supply masterbatches in granules pastes, liquid and predispersed powders. In all these four cases, the dispersion of different components is obtained at high shear by using available technologies to process the polymers. Another important aspect is the colour matching, mainly obtained by preparing a countertype on customer’s request and by imitating from the reference colour table (RAL or Pantone) or transferring one colour from one material to another.

Colour masterbatches for SILICONE

MESGO Iride Colors offers colour solutions for HCR, LSR and RTV silicone for any application for extrusion, moulding and sealant. Customized and ready to go solution in compliance with the international standard in order to achieve every customer’s need.

Available in liquid and paste form.

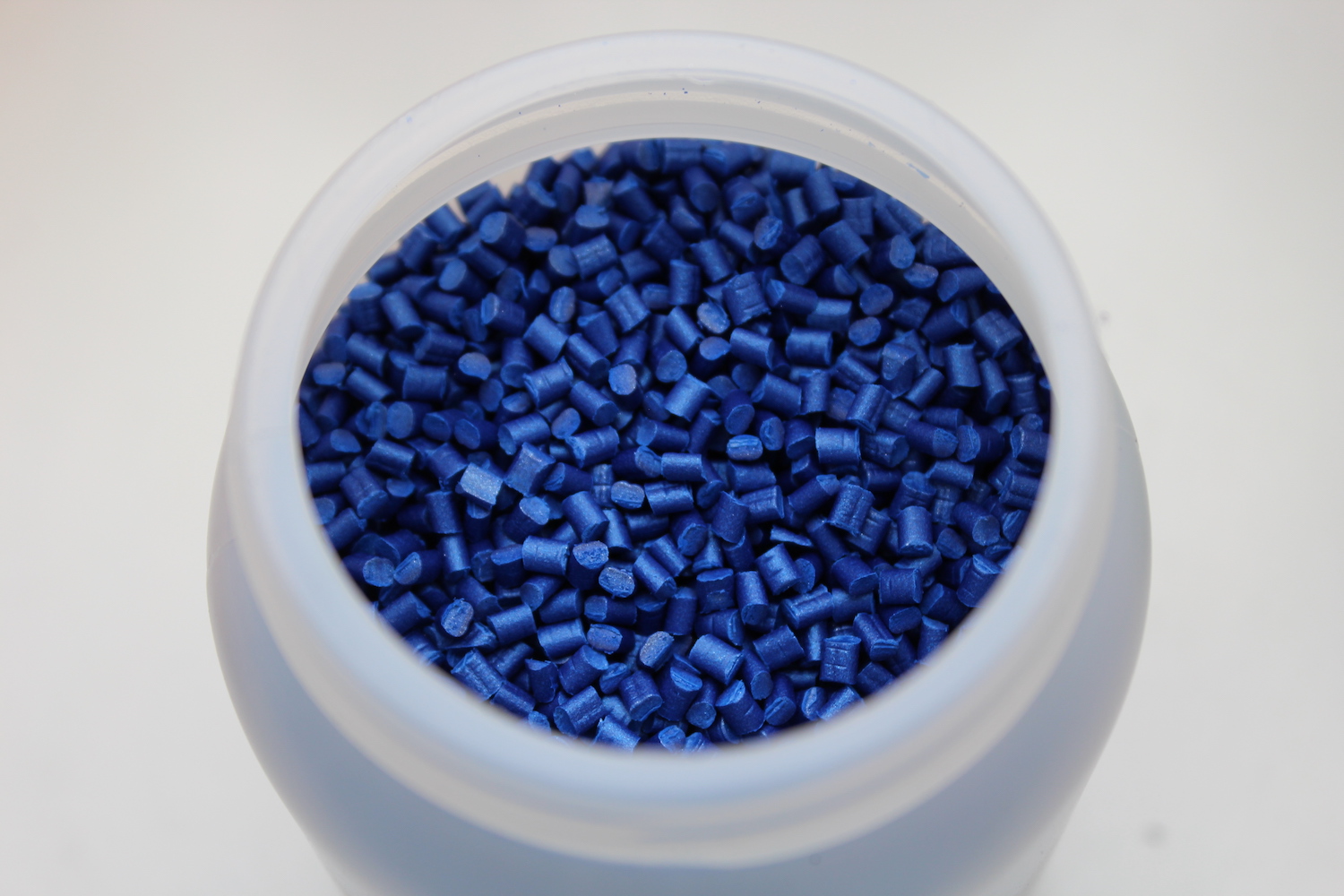

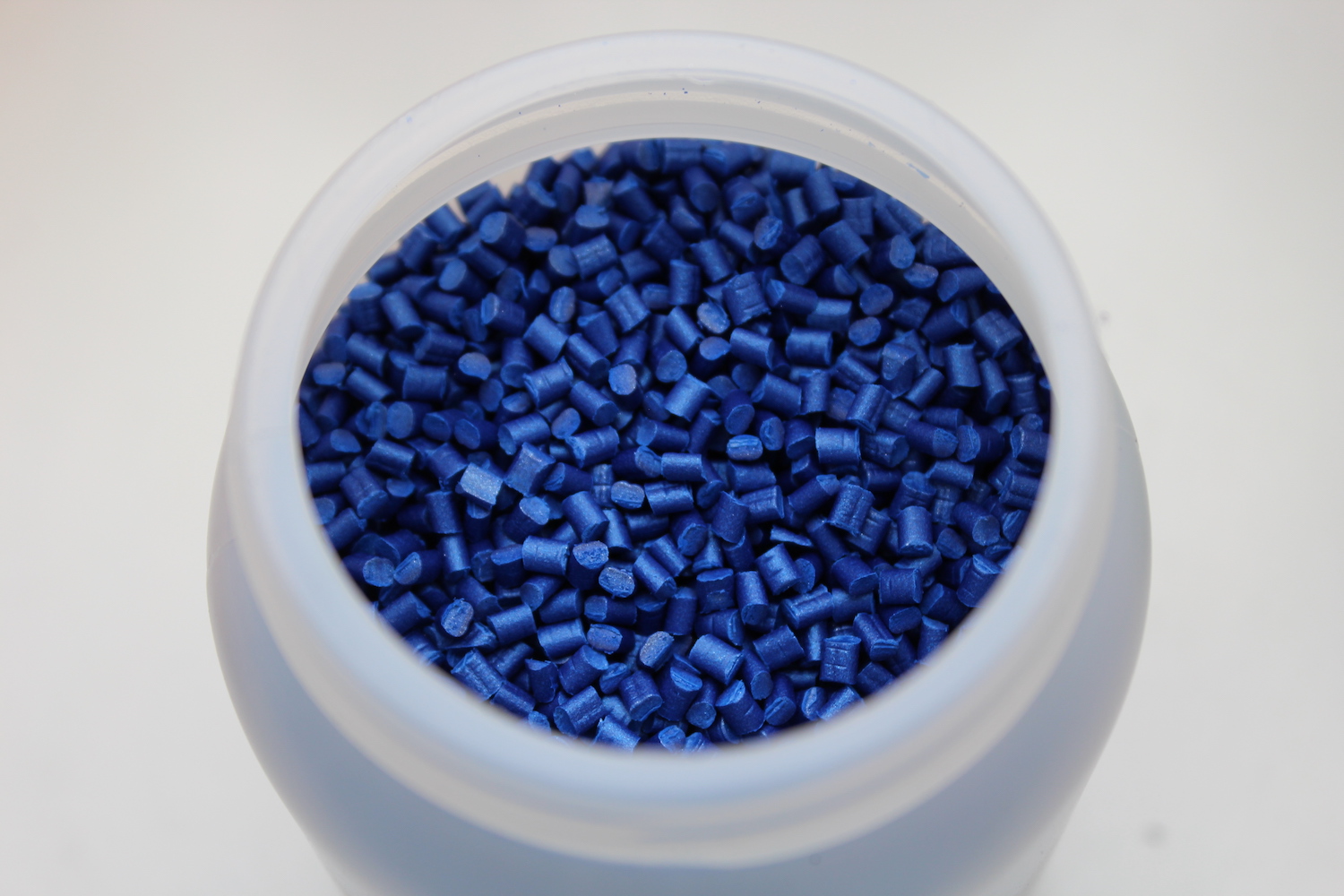

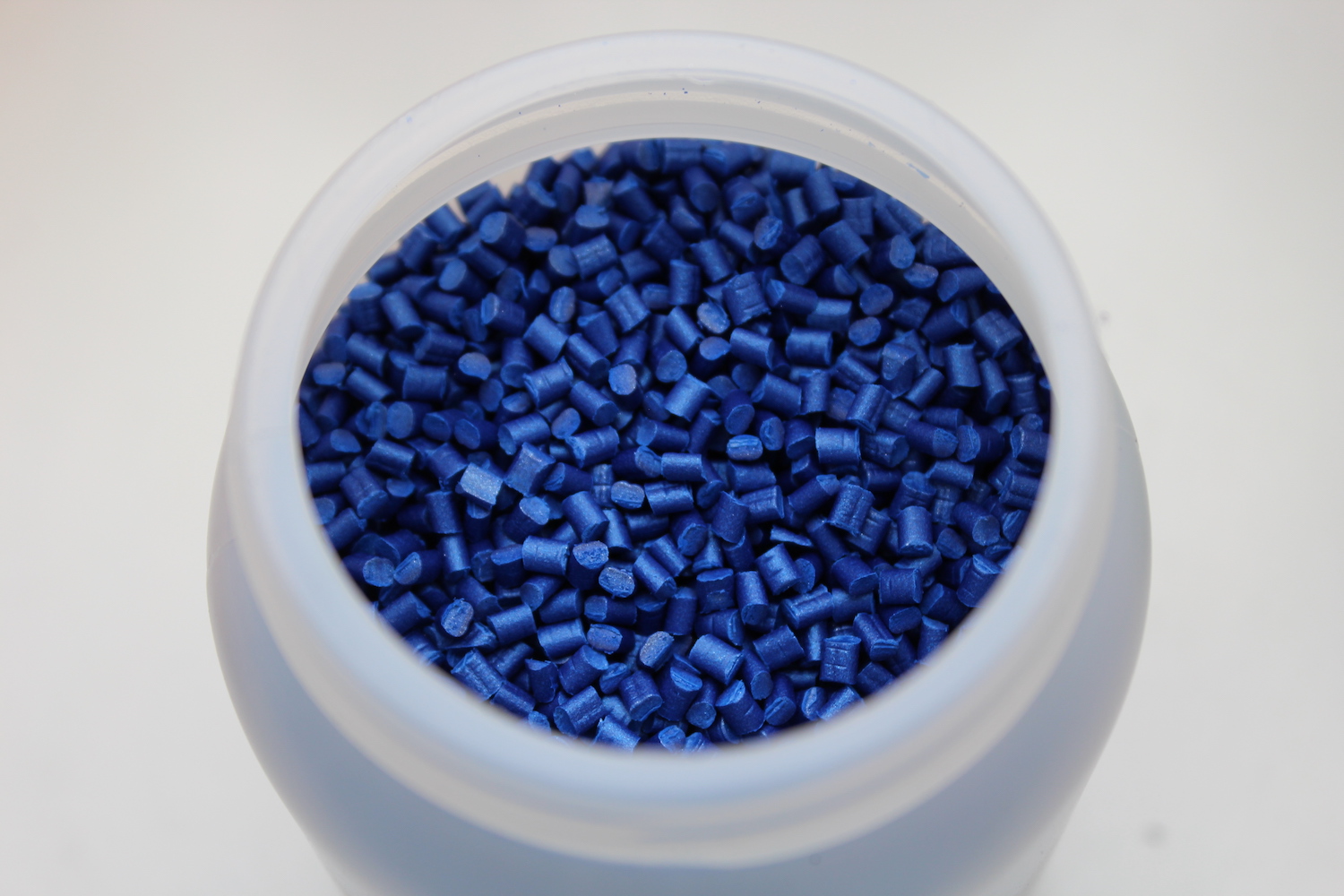

Colour masterbatches for THERMOPLASTIC

MESGO Iride colors offers masterbatches for THERMOPLASTIC compounds for extrusion and moulding suitable for EVA, LDPE, HDPE, PP, POM, PVC, GPPS, ABS, SAN, PET, PBT, PC, PMMA.

Tailor-made solutions to better meet the request of the market.

Available in granules.

Colour masterbatches for THERMOSET

MESGO Iride Colors offers a wide range of colour masterbatches for THERMOSET for extrusion and moulding, suitable for EPDM, NBR, SBR, FKM.

Tailor-made solutions to better meet market requests.

Available in granules.

REBIRTH colour masterbatches

Rebirth colours, entirely developed with recycled and post-consumer polymers, focused on environmental sustainability.

It obtained CSI recycled plastic mark according to the specific rules Doc. 002/13.

The masterbatches are supported in post-consumer polyethylene and polypropylene, the so-called rPE and rPP.

The formulations allow our customers to present colored products on the market in a totally GREEN version.

It can be used in different market segments such as Industrial (packaging, bags or shopper), consumer goods (cans, jars and bottles) and compounding.

Available in granules.

LEAF colour masterbathes

Leaf colours line has been developed for acidopolylactic polymer (PLA) but it can also be used with other biodegradable polymers, such as Polybutyrate-adipate-terephthalate (PBAT).

Thanks to a specific study on the choice of pigments which are suitable for biodegradability and compostability, our Leaf colours line guarantees the characteristics of the final product and also maintains compliance with EN 13432.

It can be used in different market segment such as Industrial, Consumer, Health care.

Available in granules.

ICYSUN colour masterbatches

IcySun, the line of colour masterbatches developed with innovative functional pigments, specifically designed to increase the solar reflectance properties in thermoplastic products, in different colours.

Developed on polyethylene, available also other bases, they can be used in various applications for outdoor and indoor use (ex: outdoor/indoor furniture, door and window frames, automotive, children’s toys, outdoor flooring, bleacher seats, boats, bicycles, outdoor houses, internal walls,..).

Available in granules.

Colour masterbatch for FILM application

Film Colour Masterbatches, focused on environmental sustainability, they are availability on regenerated polyethylene and they obtained CSI recycled plastic mark according to the specific rules Doc. 002/13.

They are suitable for different materials, such as LDPE, LLDPE, HDPE.

Film Colour Masterbatches line offers a range of products developed on polyethylene carrier and they can be used in manufacturer of shoppers, industrial- and food packaging.

Available in granules.

SUNSHINE colour masterbatches

SunShine colours are the lines of masterbatches totally developed with RECYCLED and POST CONSUMER materials.

These lines of colour masterbatches are focused on environmental sustainability, and obtained CSI recycled plastic mark according to the specific rules Doc. 002/13.

Developed through a customized process, SunShine lines offer excellent processability, good dispersion and excellent performance to the final product, to create special effects such as a pearlescent finish.

These mesterbatches are suitable for injection and blow moulding and can be used in different market segments and applications.

Available in granules.

Market segment

- Automotive

- Transportation

- Industrial

- Energy

- Building & construction

- Consumer goods

- Health care

- Printing

- Packaging

- Agriculture

| This solution allows to make direct colouring of a natural compound in extrusion. The special packaging allows to introduce the colour rope in the extruder combined with a silicone rubber compound natural stripe. |